This project required a lot of work in the development of the software but also a lot of effort in the development of the hardware. The assignment consisted of 2 main points: timely elimination of fires on agricultural machinery and their monitoring.

We needed to solve the problem of how to eliminate fires as efficiently as possible. Our solution was to deploy small development boards with a microcontroller, a wide range of sensors and Bluetooth Low Energy support. We needed to place these boards as close as possible to the engine of the machines where fires occur. We have created an effective cover for the boards, where they are protected from dirt but where the smoke from the emerging fire can still reach. These covers are equipped with a strong magnet so they can be placed on the metal motor cover.

Another problem was powering the boards. We wanted to avoid any wiring for the easiest possible installation and the supplied battery only had a 3 day lifespan. Therefore we built an LDO board to which we connected 3.7V batteries. We also optimized the firmware of the boards with the microcontroller where we disabled all unnecessary functions and sensors thus reducing their consumption. We have achieved a solution that will ensure the power supply of the boards at least for 2 months.

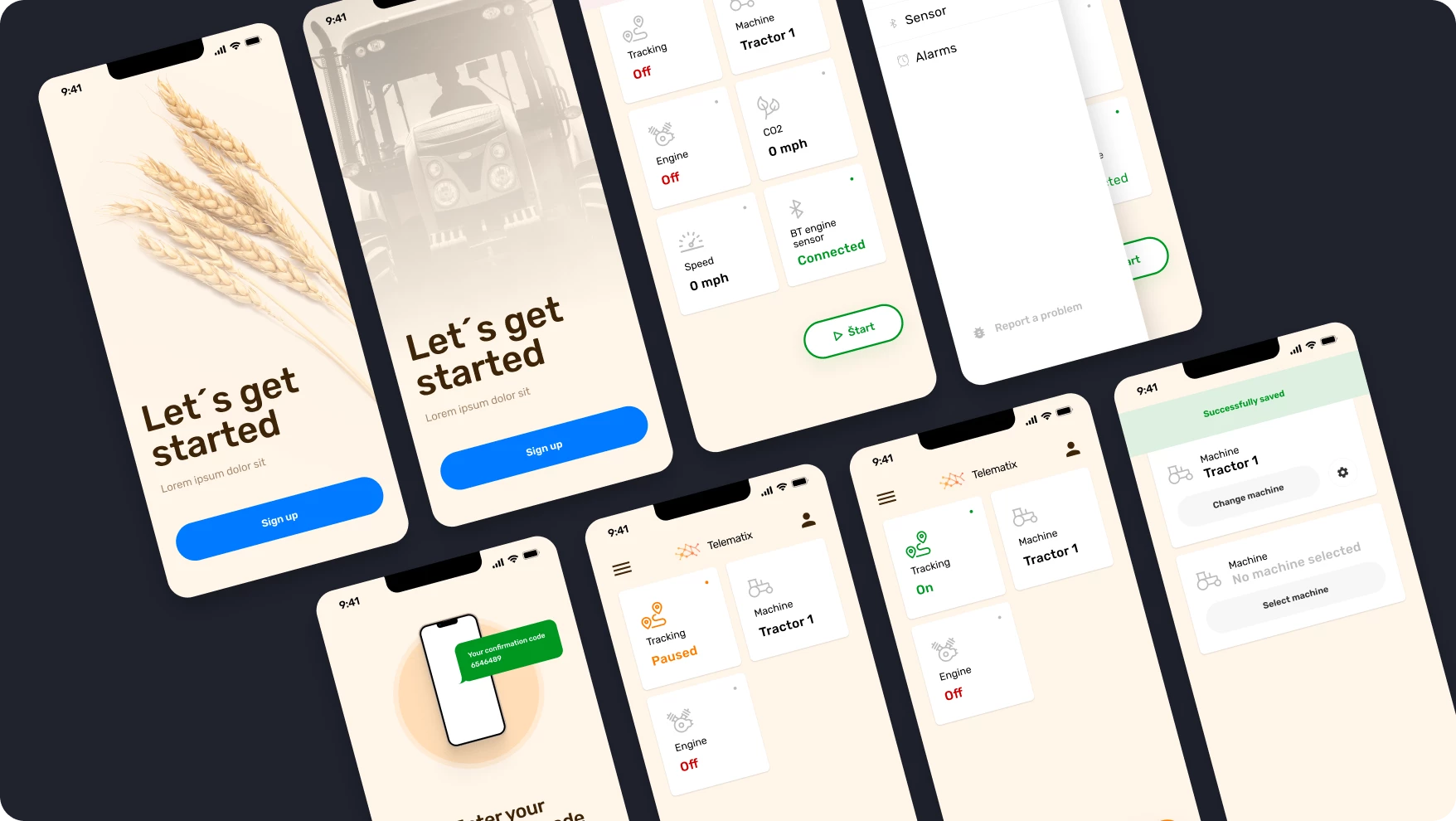

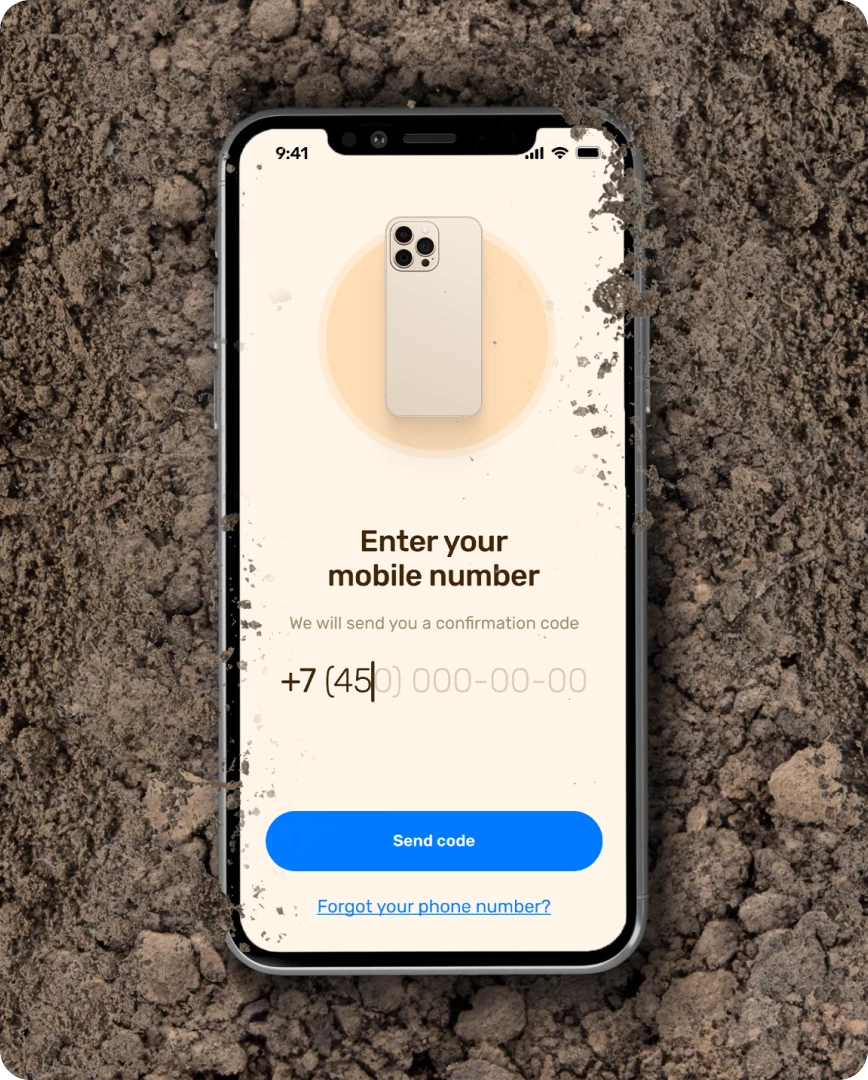

How does it all work? Each client's agricultural machine has an iPad built into it, which just needs to install the Compex Telematix app. At the start of the service the employee logs in with a 4-digit code and the application starts tracking and storing all GPS data. The application is connected via Bluetooth with a microcontroller that constantly monitors the CO2 level.

As soon as the CO2 threshold exceeds the preset value an alarm is triggered. The iPad will display a large notification and sound a loud siren. The application starts an automatic phone call to the employee and manager's phone number plus sends an SMS message with GPS coordinates. The same cautions apply when tilting the machine too much to prevent it from tipping over.

We have created an online web interface for the application with detailed statistics of all machines and their movements. Thanks to the statistics the client can see the efficiency of the movement of all machines and thus optimize the costs of operation.